|

Page 1 | Page 2 |

Page 3 | Page 4 |

|

|

|

|

Trial Court

Rules in Favor of AFTE and Named Defendants

In December of 2006 a Trial

Court ruled in favor of the Association of Firearm and Tool Mark

Examiners (AFTE) and named defendants in a lawsuit filed by AFTE

member Paul Dougherty. Judgment was entered in favor of AFTE and

the named defendants in January of 2007.

Thereafter, Mr. Paul Dougherty appealed the Trial Court decision

to the California Court of Appeal. On July 27, 2008, the

Court of Appeal issued a unanimous decision affirming the Trial

Court and awarding AFTE and the named defendants their cost on

Appeal.

The Appeals court summarized their ruling by stating,

"Stepping back from this appeal, however, there is something

very heartening about this case: A private organization

whose purpose is to ensure the integrity of expert testimony

actually had the gumption to censure a member whose

testimony bordered on the ludicrous -- roughly the

equivalent of saying that a shotgun can shoot at a right

angle. The organization painstakingly gave the errant member

multiple opportunities to explain why his testimony wasnít

as bad as it looked, and ultimately, after about four years

of internal due process, his peers censured him. In our

opinion, they didnít deserve a lawsuit, they deserve a

medal."

Read the full ruling by clicking here... (99k

pdf file)

|

|

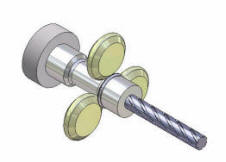

Micro Serialized Firing Pin

StudyWhat Micro

Serialized Firing Pins Can Add to Firearm Identification in

Forensic Science: How Viable are Micro-Marked Firing Pin

Impressions as Evidence?

by David Howitt, PhD, Frederic A.

Tulleners, and Michael T. Beddow Forensic Science Graduate

Group University of California, Davis

From the Executive Summary:

"Every time a semiautomatic firearm is discharged, a bullet will

leave the barrel and the cartridge case, which initially

contained the bullet and powder charge will be ejected from the

firearm. During the discharging process, working surfaces inside

the firearm impart microscopic markings onto various areas of

each bullet and cartridge case. One of these working surfaces is

the firing pin, an object that strikes the primer surface in the

base or back of the cartridge case, thereby causing the powder

charge to deflagrate and fire the bullet. These ejected

cartridge cases are one of the key pieces of evidence used in

solving firearm-related crimes. More precisely, it is the

microscopic markings, such as those impressed onto the back of

the cartridge case by the firing pin, that forensic firearms

examiners scrutinize in order to determine whether an

identification with the crime gun can be made.

This examination

and comparison process is highly meticulous, time consuming and

requires a forensic scientist with specialized equipment,

training and experience.

The transfer of intentional

microscopic impressions of intentional microscopic marking from

the working surfaces of a firearm to each fired cartridge case

was the goal behind the recent development of a micro-machining

technology designed to machine an array of microscopic

characters onto the face of a firing pin. The surface area of a

firing pin is sufficiently large enough for a wide variety of

alphanumeric characters, symbols, barcode lines, or other

encoding structures to be machined on it. Todd Lizotte of ID

Dynamics, located in Londonderry, New Hampshire, developed a

micro-machining method that utilizes an ultraviolet laser to

engrave micro-encoding structures onto firing pins. The method

is similar to that used to engrave codes on computer chips..." The transfer of intentional

microscopic impressions of intentional microscopic marking from

the working surfaces of a firearm to each fired cartridge case

was the goal behind the recent development of a micro-machining

technology designed to machine an array of microscopic

characters onto the face of a firing pin. The surface area of a

firing pin is sufficiently large enough for a wide variety of

alphanumeric characters, symbols, barcode lines, or other

encoding structures to be machined on it. Todd Lizotte of ID

Dynamics, located in Londonderry, New Hampshire, developed a

micro-machining method that utilizes an ultraviolet laser to

engrave micro-encoding structures onto firing pins. The method

is similar to that used to engrave codes on computer chips..."

Read the Full Report (582 KB pdf)

|

|

Rifling Data Search 8

Rifling Data Search

8

is the latest version of the rifling search database

application for Microsoft Access 2000, XP, 2003, or

2007.

This

version updates the data to include all data contained in the

2008 FBI GRC release.

If you are a firearm examiner and don't have access to the new federally released

database you may find this database very helpful in casework. However, this application

is not being released publicly.

Please submit a request for this application via the

Help Desk.

If you are not a Firearm and Toolmark Examiner

DO NOT BOTHER ASKING FOR

THIS APPLICATION. I will not

respond unless I can verify you work in the

discipline.

I reserve the right to limit the availability of this database

application. All

requests will be considered but I cannot guarantee your request will be approved.

Delivery of the database will be via an

approximately 2.6 MB downloadable .exe file or

.zip file.

|

|

Rifling By

Flow Forming Rifling By

Flow Forming

by BARIŞ G‹N and ILHAN G‹VEL"Flow forming of a barrel can be described as

a special application of forward flow forming which is used to

form grooves and lands inside the barrel while also forming

outside of the barrel."

"In rifling by flow forming, a barrel preform

over a special mandrel containing reverse image of desired

grooves and lands are flow formed by rollers. During the

process, the barrel material flows in axial and radial

directions. Axial flow elongates the barrel and radial flow

forms the rifling."

Read More...

|

|

|

Page 1 | Page 2 |

Page 3 |Page 4

|

|

|

|