FirearmsID.com Feature Article, October 2007

| Editors Note:

The following article by BARIŞ

GÜN and ILHAN GÜVEL of Istanbul,

Turkey describes the patent

pending manufacturing process to

produce rifled barrels by means

of Flow Forming. The

methods described in this

article appear to have merit and

are provided to inform the

firearm manufacturing and

forensic science communities.

The authors are seeking comments

and investors in bringing this

manufacturing method to the

industry. Anyone wishing

to comment on the method can

post messages on the

firearmsID.com community

forum located

here.

Contact the authors via the

links at the bottom of this

page. |

RIFLING

BY FLOW FORMING

A NEW DEVELOPED METHOD FOR RIFLING

BARRELS

APPROVED

PATENT APPLICATION : TPE 2007-G-173863

INTERNATIONAL PATENT CLASS (IPC) : F41A 21/18 , F41A 21/00

|

BARIŞ GÜN

|

ILHAN GÜVEL |

|

MECHANICAL ENG. BSc. |

NAVAL ARCHITECTURE |

|

DESIGN AND

MANUFACTURING ENG. MSc. |

AND MARINE ENG. BSc.

|

INTRODUCTION OF FLOW FORMING

Flow forming is a chipless cold forming method which is used

to manufacture dimensionally precise, round seamless hollow

components.

In flow forming; a hollow axis symmetric preform is fitted to

a mandrel. After both are made to rotate, compression forces

are applied to the outside diameter of the preform by

hydraulically-driven or ballscrew-driven CNC-controlled

rollers. For most applications three rollers are used.

By a pre-calculated amount of wall thickness reduction, in

one or more passes, the material is compressed above its

yield strength, plastically deformed and made to flow. The

desired geometry of the workpiece is achieved when the outer

diameter and the wall of the preform are decreased and the

available material volume is forced to flow longitudinally

over the mandrel.

Cross-sectional wall reductions for most materials are in

excess of 90% of the starting wall thickness. Typically, the

preform can be flow formed up to six times its starting

length before a need for reannealing of the metal is

required.

The inside surface quality of the finished workpiece is

almost same with the outside surface quality of the mandrel.

Flow forming process has two typical types which have been

appeared due to fixing necessities of preform shapes.

|

|

|

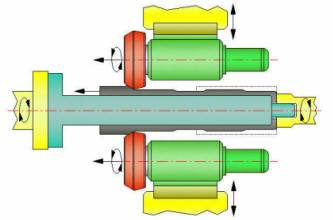

Figure-1

Forward Flow Forming |

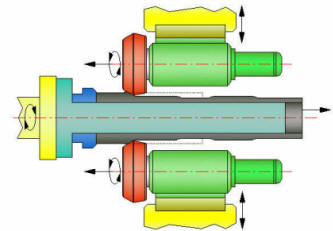

Figure-2

Backward Flow Forming |

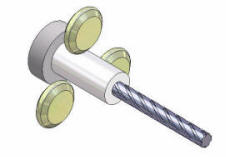

First type is forward flow forming (Figure-1) and it is used

to form preforms which have a shape with one side is

partially closed or fully closed. In forward flow forming, a

tailstock is used to fix the preform to the mandrel. The

elongation of the workpiece during forward flow forming is

at the same direction with the relative axial movement of

the rollers.

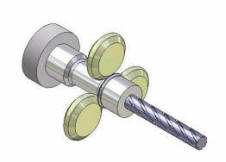

Second type of flow forming is backward flow forming

(Figure-2) and it is used to form preforms with a continuous

hole inside. In backward flow forming, a toothed ring is

used to fix the preform to the mandrel and it is also used

for reloading of the finished workpiece. The elongation of

the workpiece during backward flow forming is at the

opposite direction to the relative axial movement of the

rollers.

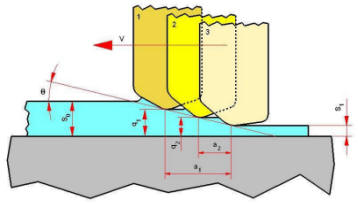

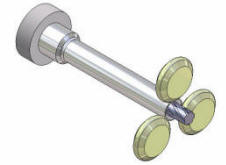

For precision long flow forming operations, typically three

rollers placed with 120° design is used. These rollers have

precalculated radial and axial offsets between each other to

achieve necessary forming conditions.

Figure-3 Typical

3-Roller Design |

Figure-4

Offsets of 3-rollers |

Main advantages of flow forming method:

-

Chipless, seamless and cold manufacturing.

-

Improved

material properties such as yield strength, fatigue life,

etc.

-

Manufacturing capability of very accurate long hollow

parts.

-

Preventing secondary operations such as turning,

grinding, etc.

-

Fast and economical production rates

compared to other methods.

As a result of the cold work (strain hardening) that occurs

during the process cycle, a flow formed component will have

considerably higher mechanical properties than the ones of

the starting material. Typically, the preform material is

plastically deformed with wall reductions in excess of 90%

of the starting wall thickness, causing a substantial

refinement of the grain structure and a total realignment of

the grains microstructure in a very uniform, axial

direction. The greater the wall reduction, the finer the

grains microstructure of the finished component. If

necessary, the grain structure can be recrystallized by a

post forming annealing cycle.

Flow forming offers the unique possibility of forming to

size a pre-hardened workpiece, thus eliminating the

difficulties and high costs associated with final machining,

grinding and honing of a hardened and distorted hollow

component. Flow forming method also allows to achieve high

dimensional accuracies and at the same time guarantee

conformance to required mechanical properties.

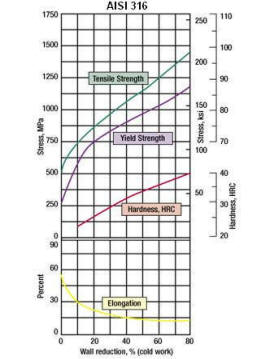

Figure-5 shows an illustration of the grains microstructure

of a preform to flow formed zone and Figue-6 shows the

improvement of mechanical properties for an AISI 316

workpiece.

|

Figure-5

Grains Microstructure |

Figure-6 |

RIFLING BY FLOW FORMING

Flow forming of a barrel can be described as a special

application of forward flow forming which is used to form

grooves and lands inside the barrel while also forming

outside of the barrel.

In rifling by flow forming, a barrel preform over a special

mandrel containing reverse image of desired grooves and

lands are flow formed by rollers. During the process, the

barrel material flows in axial and radial directions. Axial

flow elongates the barrel and radial flow forms the rifling.

|

|

|

|

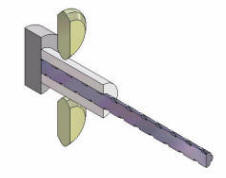

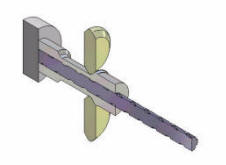

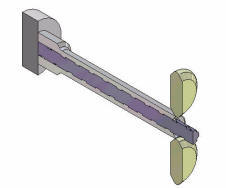

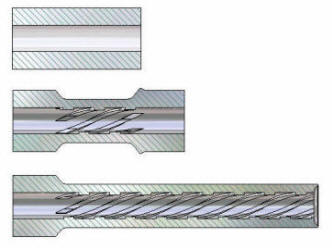

BEGINNING

OF THE OPERATION |

DURING THE

OPERATION |

END OF THE

OPERATION |

|

|

|

|

Figure-7

Rifling Process

|

Figure-8

Material Flow |

Figure 9-

Elongation and Rifling |

It is also possible to form different outside diameters

during flow forming without any stop of the rifling inside

unless each point of outer surface of rifled zone must be

less than the preforms beginning outer diameter.

Rifling by flow forming method will be the mostly using

method for manufacturing tomorrows barrels. This method has

many advantages compared with the conventional methods;

cutting (broach rifling), button rifling, forging and

electrochemical rifling.

The advantages of rifling by flow forming:

-

More accuracy with the precision

standards of flow forming

technology.

-

Stronger and / or lighter barrels with more plastic work

and strain hardening.

-

Improved fatigue life with flow formed grain structure.

-

Prevented / decreased secondary operations like turning,

grinding, etc.

-

Economical and faster production rates.

-

Useful for all light and heavy barrels from pistols to

tanks.

-

Less mass production investment costs with higher

technology.

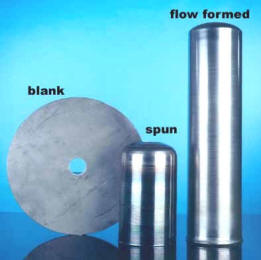

The photographs below show the Aluminum parts flow formed

and rifled for trials of the method in less than 30 seconds

with x3 times elongation in length. Grooves and lands have

been formed approximately x8 times thicker than real

applications.

Attachments:

Rifling By Flow

Forming (pdf)

Please call us for your opinions and questions.

MACDOR Machine Industry And Trade Co. Ltd.

Altiyol Gaziosmanpasa Sok. No:10/13

Kadikoy/Istanbul, TURKEY

Tel: +90216365376 Fax: +902163365381

E-Mail: info@macdor.com

Barış Gün (GSM +905434324720)

lhan Güveli

(GSM

+905423765241)

Home | Top

|