Feature Article at the Month, July 2000

This article was first published in Precision Shooting Magazine's 1995 Precision Shooting Annual and is

reprinted here with permission of the editor. This article and additional works by the author can be found at the Border

Barrels Ltd. website, www.border-barrels.com.

THE MAKING OF A RIFLED BARREL.

by

Geoffrey Kolbe

Of all the elements that make up the rifle it is the barrel that seems to

hold the greatest mystique and mystery. Anybody with rudimentary knowledge of engineering practice could see vaguely how to make the

action. Anybody with a lathe, a milling machine and the usual tooling of a small workshop - and the knowledge to use them - could

make a bolt action.

But the barrel, that is a different matter. How do you drill such a long straight hole to form the bore? How

is the rifling put in? How is the shiny finish in the barrel achieved? And above all, what is that special something that

differentiates a so-so barrel from a hummer?

Each operation in the making of a rifle barrel requires a special machine tool rarely found outside a barrel shop. That said, there

is no real mystery in making good rifle barrels. But it does take care and attention to detail. In this article I will outline the

main processes involved in turning a bar of steel into a rifled barrel, indicating where barrel makers differ in their approach.

The United States is the home of the custom barrel maker and there are literally hundreds of small barrels

shops up and down the country - some still using unbelievably primitive equipment - who make barrels to the customers

specifications. There are also some very large barrel makers who make barrels primarily for the trade. The common denominator is

that making barrels is all they do. Very little of the turnover of these barrel makers comes from making actions or rifles or doing

other gunsmithing. This picture contrasts very markedly with the rest of the world - except Australia where a country of 15 million

population supports at least three barrel makers!

Europe, with a population approaching three quarters of a billion has less than ten barrel makers, of whom

only one is a "small" custom shop. Unlike the United States, the European tradition is that a rifle manufacturer will make

everything in house and not subcontract to specialist manufacturers. There are exceptions such as Lothar Walther in Germany and

Unique in France, who occupy the position of Douglas or Wilson Arms in the U.S. supplying barrels in quantity to the trade and also

to the retail public. Great Britain, once the home of a vast gun trade centered in London and Birmingham, now only has two barrel

makers outside the ordnance industries.

THE STEEL.

The barrel of any firearm is a pressure vessel with the action serving to stop up the rear end. The peak pressures involved during

discharge are enormous, 50,000 pounds per square inch or more, and special steels are required to safely withstand these stresses.

Two classes of steel are currently used in rifle barrels. Most barrels for use on hunting rifles and in military firearms are made

from a high alloy Chrome Molybdenum steel of the sort used in high stress components such as truck axles, conrods and such. In the

United States these steels are designated as 4140, 4150 and 4340 types. In Britain these steels are better known as EN 19 or EN 24.

In target shooting stainless barrels have for the most part supplanted the use of Chrome Moly barrels. The

steel is not a true, fully austenitic stainless such as is found in cutlery. The 416 type stainless steel used in barrels is one of

a group of martensitic steels which can be hardened by heat treating like regular Carbon steels. 416 stainless is more accurately

described as a "free machining, rust resistant" steel having a high Chrome content, around 10%, but with sulphur added to

give it good machining qualities. It is widely considered that stainless barrels will have a longer life and are more accurate than

Chrome Moly barrels. If stainless barrels are "shot in" using the prescribed procedure, the barrel aquires a burnishing

which almost eliminates fouling, so making stainless barrels very easy to clean.

Because stainless steel is more expensive than Chrome Moly steel and it is more difficult to black due to the

Chrome content, high production makers of hunting and military rifles prefer to use Chrome Moly steels. But target shooters who want

the best possible accuracy from their barrels are almost without exception choosing "stainless" barrels these days.

The tensile strength of the steel is measured as the force required to break a rod of steel having a one inch

cross sectional area by pulling it from its ends. The tensile strengths of steels used for making barrels should exceed 100,000 lb

per square inch giving at least a factor of two safety margin over the chamber pressures experienced during firing. But the impact

strength of the steel is probably even more important, this being the ability of the steel to withstand a sharp knock without

breaking. Generally speaking, the tensile strength of a steel can be increased by hardening it. But as the hardness is increased, so

the steel becomes more brittle and it becomes more susceptible to fracturing from a hard knock or sharp impact - or setting off a

small explosion inside a tube of the stuff! A trade off must therefore be made of tensile strength against impact strength and for

barrel steel the resultant hardness settled on is usually between 25 and 32 on the Rockwell C scale.

The heat treatment and other production processes involved in making the steel bar leave residual stresses,

which can result in the bar bending as steel is removed in making the barrel. The stress can be relieved by putting the steel in an

oven and taking it up to 600 C, then allowing it to cool very slowly over the next twelve hours or so. Barrel steel is usually

double stress relieved to make absolutely sure it stays straight through the various machining processes.

DRILLING THE HOLE.

"What ever you make in life, you have to start with a hole." - Ernie Stallman,

Badger Barrels, Wisconsin.

Anybody who has tried to drill a straight hole more than an inch or so deep with an ordinary

twist drill will know the problem. No matter how careful you are in lining the drill up to start with the hole will wander and bend

and the drill will not come out quite where you expected. So how is it possible to drill a hole several feet down a rifle barrel and

for the drill to come out to within a few thousandths of an inch of the centre?

The answer of course, is not to use a twist drill. Special drilling machines known as Gun Drills

or Deep Hole Drills are used to drill deep accurate holes. On most older Gun Drills it is the barrel itself which is rotated at

speeds of between two and five thousand r.p.m. and the stationary drill is fed through a tight fitting guide bush into the end of

the barrel. The drill bit itself is asymmetric, cutting on one side only, and is make of Tungsten Carbide.

The bit has a hole through it and is mounted on a long steel tube with a V groove down its

outside. Coolant oil is forced down the tube at 1000 p.s.i or more to cool the drill and clear the swarf the drill produces. The oil

and the swarf come down the V groove on the outside of the tube, the oil is then strained to remove the swarf before returning to

the main tank. The drill progresses down the barrel at about one inch a minute, so it takes about half an hour to drill a barrel.

This process and the drills themselves have remained unchanged for the last hundred years - except that the drill tips were not made

of Carbide back then!

The finish that the drill leaves inside the hole can be very good, but that is the exception

rather than the rule. The hole is usually drilled about 5 thousandths under the size of the bore diameter and then a reamer is used

to bring the hole up to size leaving a fine finish and a hole of uniform diameter from end to end.

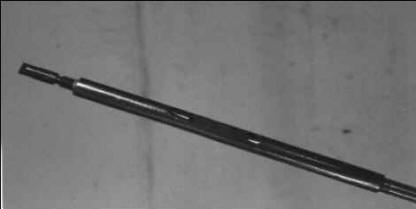

TIP OF A GUNDRILL.

Doesn't look much like a regular twist drill!. Cutting oil is pumped at high pressure through the

holes at the end of the drill. The drill only cuts on one side and the oil carries the swarf up the V groove on the outside of the

drill and drill shaft. The drill is designed so that the forces acting on the drill tip tend to keep it on the central axis of

rotation of the barrel.

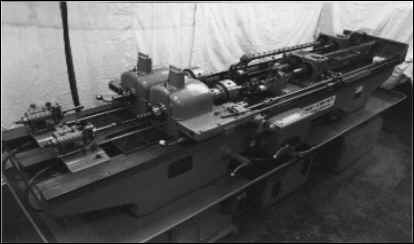

DEEP HOLE DRILLING MACHINE.

The gundrill is attached to the pressure head at the bottom of the photo, where cutting oil is

pumped down the drill shaft at high pressure. The drill is supported in the middle by a steady to give it added rigidity. The drill

passes through a series of guide bushes before entering the barrel, which is being rotated by the spindle-head at the top of the

photo. Oil is seen coming off the spout attached to the guide-bush-head and carries the swarf out from the hole in the barrel. The

oil returns the main tank after passing through strainers to remove the swarf.

REAMING THE HOLE.

"When two or three barrel makers gather together, the conversation turns to the

difficulties and problems of reaming a good hole." - Observations of a barrel maker.

Every barrel maker I can think of who cut rifles or button rifles their barrels will ream prior

to rifling. Makers of hammer forged barrels require a very fine surface finish in the bore and they invariably hone their barrels to

get the required finish.

The reamer is mounted on the end of a long tube through which the coolant oil is pumped, but at

far lower pressures than are used in the Gun Drill. Now it is the reamer that is rotated, at about 200 rpm and the barrel is pulled

over the reamer at about one inch a minute.

Harold Hoffman's books on barrel making give descriptions and drawings of bore reamers which will

be very familiar to readers of "Gunsmithing" by Roy Dunlap published in 1950, and even more familiar to readers of

"Advanced Gunsmithing" by W.F.Vickery published in 1939! Would-be barrel makers who read these hallowed texts can be

forgiven for thinking that reaming technology has not advanced much in sixty years and has reached level of perfection where

improvement is difficult. Nothing can be further from the truth. Over the past few years there has been a quiet revolution in reamer

technology and these days most bore reamers are made of Tungsten Carbide instead of High Speed Steel.

Reamers made from Carbide last at least ten times longer than HSS ones and generally leave a

superior surface finish. They can also be run at much higher feeds and speeds - 500 R.P.M and 10 inches a minute is not uncommon!

Reamer shape has also changed. Reamers have become shorter and shorter over the past ten years and do not have pilots on them as

reamers of old.

Reaming a good hole is still something of an art though. Several barrel makers I know refuse to

buy bore reamers claiming that you cannot buy a good bore reamer and I have to say there is something to that. Barrel makers who do

buy their bore reamers get them from the reamer makers who advertise in this magazine, (Precision Shooting), but generally the

reamer needs some hand honing to get it to "run right" and leave a good finish. In my experience, the only reamer maker

whose reamers do not require attention before using them is Dan Green of Forgreens. Dan is a really great reamer maker and his

chamber reamers are also quite outstanding - I only wish he would make reamers in Carbide!

After reaming, the resultant hole has a good finish and has good dimensional uniformity along its length. The barrel is now ready

for rifling.

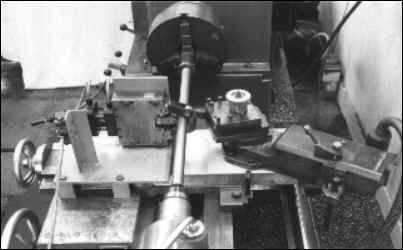

BORE REAMER ENTERING THE BARREL.

After the barrel has been drilled, it is reamed up to the bore size. Here a bore reamer enters

the barrel as copious amounts of cutting oil flushes the chips away.

CUT RIFLING.

"Cut rifling is a real hard way to go. I can't think why anyone should go that

route." - I forget the name of the Australian reloading tool maker who made this observation, but there have been times

when I have heartily agreed with him!

There are currently three main methods by which rifling is put into the barrel. By far the oldest

method, invented in Nuremberg in around 1492, is the cut rifling technique. Cut rifling creates spiral grooves in the barrel by

removing steel using some form of cutter.

In its traditional form, cut rifling may be described as a single point broaching system using a "hook" cutter. The cutter

rests in the cutter box, a hardened steel cylinder made so it will just fit the reamed barrel blank and which also contains the

cutter raising mechanism.

The cutter box is mounted on a long steel tube, through which coolant oil is pumped, and which

pulls the cutter box through the barrel to cut the groove. As it is pulled through it is also rotated at a predetermined rate to

give the necessary rifling twist. A passing cut is made down each groove sequentially and each cut removes only about one ten

thousandth of an inch from the groove depth.

After each passing cut the barrel is indexed around so that the next groove is presented for its

passing cut. After each index cycle the cutter is raised incrementally to cut a ten thousandth deeper on the next cycle, this

process being continued until the desired groove diameter is reached. It takes upwards of an hour to finish rifling a barrel by this

method.

The rifling machines found in custom barrel shops are invariably Pratt & Whitney machines.

For the first world war some thousands of "Sine Bar" riflers, so called because a sine bar is used to determine the rate

of twist, were built to satisfy the demand for barrels at that time. These belt driven single spindle machines weighed about a ton

and were suitable for the wooden floored workshops of that era. After WW1 many of these machines became available quite cheaply on

the surplus market and so in the inter-war years these were the standard rifling machine in barrel shops across the World.

P & W SINE BAR RIFLING MACHINE.

The classic rifling machine! P & W started making these machines over 100 years ago and these

"Universal" rifling machines formed the backbone of the barrel making business up until WW2. This one was made in 1895!

At the start of World War Two, Pratt & Whitney developed a new, "B" series of

hydraulically powered rifling machines, which were in fact two machines on the same bed. They weighed in at three tons and required

the concrete floors now generally seen in workshops by this time. About two thousand were built to satisfy the new demand for rifle

barrels, but many were broken up after the war or sold to emerging third world countries building up their own arms industry.

Very few of these hydraulic machines subsequently became available on the surplus market and now

it is these machines which are sought after and used by barrel makers like John Krieger and "Boots" Obermeyer. In fact,

there are probably less of be "B" series hydraulic riflers around today than of the older "Sine Bar" universal

riflers.

PRATT & WHITNEY HYDRAULIC RIFLING MACHINE.

In the late 1930's the venerable Sine Bar rifler was replaced by the "B" series

hydraulic rifling machines. These twin spindle machines were altogether more massive, more rigid and more powerful. During WW2, much

faster methods of rifling were developed and superseded single point cut rifling as a technology for mass production of rifled

barrels. These machines remain, then, the zenith of cut rifling technology.

During World War Two several other methods of rifling barrels were developed which greatly

speeded up and simplified the process. So the Pratt & Whitney "B" series of Hydraulic riflers remain the last word in

cut rifling machine technology.

Due to the very limited availability of these machines there are several barrel makers who have

made their own machines. But, as will be appreciated from the description of the process above, these machines are complex and

expensive to build.

The techniques of cut rifling has not stood still since the end of the war though. Largely due to

the efforts of Boots Obermeyer the design, manufacture and maintenance of the hook cutter and the cutter box has been refined and

developed so that barrels of superb accuracy have come from his shop. Cut rifled barrel makers like John Krieger (Krieger Barrels),

Mark Chanlyn (Rocky Mountain Rifle Works) and Cliff Labounty (Labounty Precision Reboring) who are fast growing in prominence for

the quality and accuracy of their barrels, learned much of their art from Boots Obermeyer, as did I.

In Europe, Shultz & Larson in Denmark were the outstanding protagonists of the cut rifling

method and were making 8000 barrels a year. But adherence to workshop methods more suited to the beginning of this century, rather

than its end, allowed competitors with newer technology to take their markets. They closed their doors just a few years ago.

Grunig & Elminger in Switzerland cut rifle their barrels, and Furlac in Austria still make

their larger calibre hunting barrels by cut rifling. Tikka, the Finnish hunting rifle makers used to cut rifle some of their

barrels, but now that Sako have taken them over, their barrels are made by Sako whose barrels are hammered.

RIFLING "HOOK" CUTTER.

The heart of the cut rifling method, making and

maintaining these cutters require great skill.

RIFLING CUTTER HEAD.

The "hook" cutter is seen sitting in its box in the middle of the cutter head. The

cutter sits on a wedge and as the screw at the end of the head is turned, it forces the wedge under the cutter so raising it to

increase the depth of cut.

BUTTON RIFLING.

"Any fool can pull a button through a barrel!" - Boots Obermeyer.

Up until WW2 rifling was the most time consuming operation in making a rifle barrel and so a lot

of effort was put into finding a way to speed up this process. Button rifling is a process that has been flirted with on and off by

various large ordinance factories since the end of the 19th century. Today, button rifling is a cold forming process in which a

Tungsten Carbide former, which is ground to have the rifling form in high relief upon it, is pulled through the drilled and reamed

barrel blank. The lands on the button engrave grooves in the barrel as it is pulled through.

The machinery is quite simple. The button is mounted on a long rod of high tensile steel which is

passed through the barrel blank and attached to a large hydraulic ram. The button is mounted in a "rifling head" that

rotates the button at the desired pitch or twist as the button is pulled through the barrel. The process takes about a minute to

complete.

RIFLING BUTTONS.

These are "pull" buttons that are pulled through the barrel. The left hand button is a

simple rifling button. The slots cut into the button mean the button does not engrave the barrel in that area and as a result, lands

are left in the barrel. The lands left by this simple rifling button tend to have raised burrs on their edges. The combination

button on the right has a sizing button to follow the rifling button which presses the burrs back down, so leaving the land tops

conforming to the bore circle as they should.

BUTTON RIFLING MACHINE.

The barrel can be seen in the middle of the picture. The right hand end of the barrel is held

against a thick steel pressure plate. The button is seen about to enter the barrel at its left hand end. At the other end of the

barrel the pull-rod is attached via the twisting-spindle to a frame, which is pushed by the two hydraulic rams above and below the

barrel. As the frame is pushed to the right the button is pulled through the barrel - it needs a lot of force to pull a button

through a barrel! The twisting-spindle is driven by the rack and gear seen at the right hand end of the photo so that the button is

positively driven at the desired rifling twist, preventing button slippage.

Breaking the pull-rod or pulling the button off the pull rod is a constant danger in

"pull" button rifling, so there are several manufacturers like Hart, for example, who prefer to push the button through

the barrel. In this version of the method the button is not attached to the rod, which simply pushes the button up the barrel under

the influence of a large hydraulic ram. The trick here is to support the push-rod as it enters the barrel to stop it buckling from

the huge forces involved.

There is much opinion that "pull" button rifling is best because the button is kept

straight and true as it is pulled through, whereas when pushing the button though the barrel there is an inevitable tendency for the

button to tip and yaw so leading to variable bore dimensions. Push-buttoning protagonists deny that this is a problem however - as

of course, they would!

Whilst the process is simple, the technology required to get good results is quite advanced which

is why it was not until the middle of this century that it became a generally used technique. It was perfected in the late 1940's at

the Remington factory at Ilion largely due to the efforts of Mike Walker, who used the workshop of Clyde Hart in nearby Lafayette

for some of the experimental work. The button must be very hard and also tough enough not the break up under the stresses involved

as it is pulled through the barrel. The lubricants used to keep the button from getting stuck in the barrel must not break down

under the very high pressures involved - it takes around 10,000 pounds of force to pull a button down a barrel. The sort of

lubricants used in the press moulding business are what button barrel makers pick through to see what suits, though most makers of

button rifled barrels are very secretive about lubricant they use!

Button rifling in its common form is an American development and the overwhelming majority of

barrels made in the US are rifled this way. Custom shops such as Hart, Lilja, Shilen and the large high production barrel makers

like Douglas and Wilson Arms use the buttoning method to rifle their barrels. The technology has spread and there are a few other

small custom barrel makers around the world who do button rifling. Neville Madden (Maddco) and Dennis Tobler in Australia. Anshutz

in Germany, better known for their .22 target rifles but also a large producer of hunting rifles also button their barrels.

In Europe, where larger more centralised armament factories predominate, the cold forging method

of making "hammered" barrels is generally preferred.

HAMMER RIFLING.

The technique of hammer forging rifle barrels was developed by Germany before WW2 because the

MG42 machine gun, with 1200 rounds per minute rate of fire, positively ate barrels. The first hammer rifling machine was built in

Erfurt in 1939. At the end of the war it was shipped down to Austria ahead of the advancing Russian army, where American technicians

were able to get a good look at it.

In this process the barrel blank is usually somewhat shorter than the finished barrel. It is

drilled and honed to a diameter large enough to allow a Tungsten Carbide mandrel, which has the rifling in high relief on it, to

pass down the blank. The blank is then progressively hammered around the mandrel by opposing hammers using a process called rotary

forging. The hammered blank is squeezed off the mandrel like tooth paste and finishes up 30% or so longer than it started.

Today, barrel hammering machines are built by Gesellschaft Fur Fertigungstechnik und Maschinenbau

(GFM) in Steyr, Austria. They cost about a half a million dollars and can spit out a barrel every three minutes. These machines have

reached a very high degree of development and are so sophisticated that they will not only hammer the rifling into the barrel, but

it is also possible to chamber it and profile the outside of the barrel all in the one operation. Only large scale arms

manufacturers and ordinance factories have pockets deep enough and barrel requirements insatiable enough that they can afford to buy

and run such a machine.

Hammered barrels have never achieved much favour in target shooting. Whilst their proponents laud

the virtues of the mirror finish of the bore and its work hardened surface, which gives long life, the barrels tend to be very

variable in the uniformity of their dimensions down their length. Also, because the metal is worked completely throughout the barrel

there are considerable radial stresses induced which are difficult to remove completely by the usual stress relieving methods.

Stainless steels tend to work harden to a much higher degree than Chrome Molybdenum steels and so do not remain malleable enough to

hammer forge. Because of this, it is difficult to make stainless barrels this way. Stainless barrels are being hammer forged, but

using type 410 steel which has a lower chrome content than the regular 416 steel usually used for making barrels by other methods.

Most of the big hunting rifle makers in Europe hammer forge their barrels. Sako and Tikka in

Finland, Heckler & Koch, Steyr and Sauer in Austria. Now, Ruger in the US has started making barrels using this method.

PROFILING.

Profiling the barrel can be done on a regular lathe, but as the barrel is relatively very thin

for its length it is not very stiff it is difficult to machine the middle part of the barrel without inducing a lot of chatter,

which can ruin the finish and in bad cases even bend the barrel. Also, one is really limited to straight taper profiles achieved by

offsetting the tailstock. To reproduce the curving lines of most sporter and bigbore target rifle barrels in a reasonable time

requires the use of a proper profiling lathe which has a hydraulic copy attachment and a self centering steady.

The hydraulic copy unit has a sensitive stylus which follows the shape of the pattern, which is

usually mounted on a rail behind the lathe bed. As the automatic feed moves the saddle down the bed of the lathe, so the stylus

follows the contours of the pattern. The cutting tool is mounted on a hydraulically actuated tool post and mimics the movements of

the stylus, so reproducing the shape of the pattern.

To hold the barrel steady and stop it from vibrating a hydraulic or pneumatically operated steady

follows a few inches behind the cutter. This consists of three rollers which clamp on the barrel and which are linked so that if one

moves radially in or out then the others follow it. This allows the steady to adjust for the changing diameter of the barrel as the

tool and steady move from the thin muzzle the thick reinforce.

When profiling a barrel a lot of metal is removed and if there is any stress in the metal then

this is relieved by the removal of material. This may result in a barrel that started out as straight ending up as bent. This is not

usually a problem when cut rifling a barrel as this does not induce any stress, but button rifling induces a fair amount of radial

stress which is relieved by turning the barrel down. What happens then is that as you remove metal from the outside so the

dimensions on the inside grow larger. If you turn a sporter barrel with a skinny muzzle from a buttoned blank then you find the

barrel is bell mouthed and the bore diameter is a thou' or more bigger at the muzzle than the chamber - definitely, not good!

Buttoned barrel blanks have to be stress relieved before profiling to prevent this expansion at the muzzle.

PROFILING LATHE.

The cutting tool is attached to a hydraulic copy unit, the pattern following stylus of which can

be seen in the bottom right hand part of the picture near the pattern barrel. The three jaw self centering steady can be seen in the

middle of the picture. This follows just behind the cutting tool, keeping the barrel rigid.

LAPPING.

"No need for it, just wears the barrel out!"- P. O. Ackley.

Lead lapping the barrel is done to polish the bore and remove machining marks and also to remove

any tight spots in the barrel and make it dimensionally uniform end to end. If you were to sit down and write a top ten list of

barrel makers, past or present, almost all would lap their barrels.

This process is usually done by hand, though the process is mechanized in larger shops. It also

acts an inspection process for the barrel maker who can feel what is going on up the barrel.

First, the lapping rod (an old cleaning rod) is passed up the barrel to within about four inches

of the end and then, with the barrel held vertical, molten lead is poured into the barrel. The lead freezes onto the end of the

lapping rod forming a cast which precisely matches the inside form and dimensions of the barrel. The lead lap is then pushed out and

smeared with lapping paste like that used for valve grinding. The lead lap is then pulled and pushed up and down the length of the

barrel for several hundred strokes occasionally adding more paste or oil. Because the big particles of grit are embedded more deeply

in the lead than the small particles there is an even bearing pressure from all the particles of grit onto the steel of the barrel.

The net effect is to polish the barrel rather than scratch it which would leave a mat finish.

Lapping the barrel adds between one and three tenths of a thou' to the bore and groove diameters

of the barrel and is used by most small custom barrel makers as the finishing process on the inside of the barrel. Lapping a barrel

will improve the performance of almost any barrel - in some cases, startlingly so!

Generally, lapped barrels will shoot well from the word go where as the same barrel not lapped

may take a thousand rounds or so until it starts performing at its best. Contrary to Ackley's dictum, lapping will add to the

accurate life of a barrel, not detract from it.

LAPPING A BARREL. Yours truly taking some exercise at the lapping bench!

WHAT MAKES A BARREL ACCURATE.

Some people want their barrel dimensions accurate to the nearest tenth of a thou'. But in truth,

the golden rule seems to be that the groove diameter must be same or less than the bullet diameter to get good accuracy. It does not

seem to matter how much less you make it, one tenth of a thou' or one thou' - so long as it is less.

As a general rule, barrels with shallow grooves are better than those with deep grooves because

the bullet will be distorted less. Barrels with shallow grooves reach their best quicker than deep grooved barrels - but they

certainly do not last as long.

Some people say that the finish in the barrel is important and the better the finish, the better

the barrel. What seems to be true is that if the finish is too good, less than 10 microinch roughness, then metal fouling tends to

become a problem. It seems that in a "rough" barrel, the bullet rides on the high spots and so there is relatively little

friction. But the smoother the barrel gets then the greater the surface contact with the bullet. The friction goes up and more

bullet jacket gets left behind. Of course, if the barrel is too rough, then this just picks up metal and acts like sandpaper on the

bullet. But there is a band of surface roughness where metal fouling is minimized which is between 10 and 20 microinches.

There have been many claims over the years that different forms of rifling profile will give

better results. But so far, there is no conclusive proof that the so called concentric form almost universally used these days is

any worse than any other - or any better!

What is important is that the bore and groove dimensions are uniform down the length of the

barrel, that the twist rate is uniform and that the groove circle is concentric with the bore. Many think a slight choke at the

muzzle end of a ten thousandth or so will improve accuracy. But bench rest shooters have shown that parallel barrels seem to win

more matches than choked ones. The exception is barrels which shoot lead bullets, like .22 Rimfire barrels and air rifle barrels.

These barrels definitely shoot better if there is a slight choking in the barrel. The barrel should also be completely free of

stress so that as it warms up during a course of fire the barrel does not bend so leading to group shifting.

WHICH METHOD MAKES THE BEST RIFLE BARRELS?

Here that at Border Barrels we used to exclusively cut rifled until the demand for our barrels

outstripped capacity. The principle problem was (and is) the availability of cut rifling machines - you don't exactly trip over them

at machinery auctions. Also, a high level of skill is required to maintain the tooling. Like all old technologies, cut rifling is

slow and requires a high level of skill to make and maintain the tooling. This makes it expensive. The other side of the coin is

that the tooling is readily made with simple machine tools and is very flexible - by which I mean that a large range of twists and

bore dimensions and numbers of grooves are readily achieved using the same cutter and cutter box. This makes cut rifling is an

efficient way to go if you are making custom barrels in one's and two's to a customers specific requirements and you can charge a

hefty sum for your efforts. But cut rifling machines are expensive to buy and expensive to operate.

Having started out as a custom barrel maker making custom barrels in one's and two's, we found

that more and more of our work was in longer and longer runs of barrels of the same type and when it takes an hour or more to rifle

a barrel, it sure leads to long days.

So we invested in plant for button rifling. The button rifling machine is relatively simple and cheap to build, (compared to a cut

rifling machine), and the buttons are also available and very cheap - in terms of tooling cost per barrel. Also, no real skill is

required to pull a button down a barrel. Boots was right! What all this is leading up to is that we have experience in making

barrels using the two methods most commonly used in making top quality target rifle barrels and we can be pretty objective about the

pro's and con's of cut rifling and button rifling. Hammer forged barrels do not have a very visible presence in the accurate gun

world, so I will confine this discussion as to the relative merits of cut versus button rifled barrels.

If it is so easy to rifle barrels using a button, why do some barrel makers persist in the

difficult, time consuming art of cut rifling? As outlined above it is critical in an accurate barrel that bore and groove dimensions

be uniform end to end. When buttoning a barrel then it is critical that the steel be very homogeneous and of uniform hardness along

the bar. If not then the button will engrave deeper into the soft parts than the hard parts so giving varying dimensions down the

barrel. The button rifled barrel maker is very much in the hands of his steel mill to supply him with uniform, homogeneous steel.

The depth of engraving of the button depends also on the thickness of the bar at the point where

the button is. If the bar is thin then the metal can then just expand elastically allowing the button the pass without doing much

engraving. If the bar is thick there is more resistance to the button and so it will engrave deeper. To hope to get uniform bore

dimensions it is critical to pull the button through a blank which has the form of a parallel cylinder. A button rifled barrel must

be rifled and then stress relieved before it is profiled. There is always the problem that any residual stresses are going to make

the barrel move when profiling, so leaving you with a barrel that is bent or bell-mouthed.

The tendency of the bore dimensions of non-stress relieved buttoned barrels to expand on profiling the outside had been used by some

manufactures to advantage. Barrels having bore dimensions that vary over the length can be made to shoot well if the muzzle end is

the tightest part of the barrel. The bullet will then make a clean exit without gas leaking around the sides to destabilize it. When

mass producing barrels it is then possible to allow a fair degree of variation in the bore and groove dimensions down the barrel,

provided some choking at the muzzle is included in the manufacturing process. If the buttoned barrel blank is profiled so that the

last inch or so at the muzzle end is left at a larger diameter than the rest of the barrel, the expansion of the bore dimensions

will be least at the muzzle so leaving a slight choke. That is why the barrels on almost all .22 target rifles look the way they do.

Cut rifling a barrel puts no stress in the steel and so it is possible to profile the barrel

after the drilling stage. Any moving around the barrel is going to do will be done and the barrel can be reamed and rifled after

profiling. The problem of stress induced changes in bore dimensions during manufacture can be eliminated.

When making fluted barrels, the fear is always there that putting, say, six flutes on the outside

of the barrel will leave the bore shaped like a hexagon instead of round. (Like it should be!) With cut rifling, the barrel can be

completely profiled and fluted after the drilling stage and then reamed and rifled. All the niggling doubts as to whether fluting

the barrel will ruin it can be dispelled if it is done this way - but this manufacturing route in not available to you when you

button rifle a barrel.

The exact twist of a buttoned barrel is also unpredictable. The button tends to slip in the

barrel so what set out to be a 12 inch twist may end up as a 12.5 inch twist. This is not a problem if the twist is uniform, but if

it varies down the barrel - particularly if it slows - then like as not, it will not shoot.

Another problem, is that the button may not engrave as deep on one side as on the other so

leaving a groove circle that is not concentric with the bore. The result is bullets leaving the barrel which are not balanced and so

unstable. This becomes less of a problem if you have lots of shallow grooves instead of a few deep ones.

Selection is the key to success with buttoned barrels and barrel makers like Hart, Douglas and

Shillen grade their barrels by using an air gauge to judge the uniformity of bore and groove dimensions in each barrel. Ultra

Premium Select barrels carry a premium price tag and are used by the bench rest fraternity. The lower grades get turned into regular

target barrels and sporter barrels.

None of these problems arise in traditional single point cut rifling a barrel. Groove circle and

bore are always very concentric. Because very little work is being done on each passing cut the twist rate is very consistent and

very uniform. As a general rule, I find that button rifled barrels are not as uniform in bore dimensions straight off the machine as

a cut rifled barrel. Button rifled barrels usually need a deal more lapping than a cut rifled barrel due to this problem.

Exact dimensions are easier to achieve by cut rifling and are not dependent on the hardness or

thickness or type of steel as they are in buttoning. No stress is put into the barrel by cut rifling so no stress relieving is

needed.

Many people think that the superior finish in a button rifled barrel must mean it will shoot

better. In the first place, the surface finish that counts is the longitudinal surface finish, down the length of the grooves. The

tool marks in cut rifled barrels go in just this direction, so causing mini-lands which are quite uniform down the length of the

barrel. The transverse "roughness" caused by the lands are never viewed as an impediment to accuracy, so the mini-lands

left by the tool marks in cut rifled barrels will also not affect accuracy. In the second place, the final finish in the barrel is

determined by the lapping. If the cut rifling barrel maker has paid attention and kept his cutter sharp to minimize tool marks, then

after lapping only a very experienced eye will be able to tell the difference between the cut rifled and the button rifled barrel.

I believe that you are more likely to get a top of the line tack driver by cut rifling a barrel

than by any other method. Bench rest shooters in the States are rediscovering the cut rifled barrel and there may well be a

revolution when cut rifled barrel makers, who have been quietly persisting over the years with this demanding technique, find

shooters at the very highest levels of accuracy banging on the doors of their barrel shops. |