Feature Article, January 2004

This article was

originally published in the Winter 2003, Association of

Firearm and Toolmark Examiners (AFTE) Journal (AFTE Vol.

35/#1 Winter 2003). It is being reprinted here with

the permission of the AFTE Editor, Matt Noedel.

| Validation

Study of Electrochemical Rifling

|

By: Charles S. DeFrance and

Michael D. Van Arsdale, Federal Bureau of Investigation,

Washington, D. C.

Key Words: electrochemical

machining, electrochemical rifling, ECR, validation study

ABSTRACT

Electrochemical machining is being

used by Smith & Wesson to rifle many of its revolver

barrels. This paper provides a description of this

manufacturing process and a study that was conducted to

evaluate whether or not these barrels will mark bullets in a

repeatable and unique manner. This validation study of

firearms/toolmarks identification as it applies to

electrochemical rifling found that this manufacturing

technique does produce unique, reproducible, and

identifiable microscopic marks.

INTRODUCTION

Since 1993, Smith & Wesson has been using an

electrochemical machining technique to rifle most of their

revolver barrels. The only revolver barrels that are still

broach rifled are .22 caliber barrels and ported barrels.

The manufacture of electrochemically rifled (ECR) barrels

begins with the same steps as conventional broach rifling.

The barrels are drop forged from bar stock, annealed, and

wheel abraded to remove scale. During the annealing

process the barrels have a tendency to bend and are

therefore put through a straightening operation. The barrels

are next drilled and reamed using conventional machining

tools and the forcing cone is made with a tapered reamer.

The barrels are then ready for rifling.

The electrochemical rifting machines arc made by Surftran

and were specifically designed for Smith & Wesson. Each

machine runs two independent workstations, each one with a

single electrode manufactured by Mechanical Plastics. They

are constructed of a two-inch long plastic cylinder with

metal strips spiraling down its exterior. The metal strips

are in the desired dimensions of the grooves, are at the

appropriate rate of twist (1 turn in 18.75 inches for .357

Magnum), and are slightly inset in the plastic cylinder. The

barrel is placed in the machine and is held stationary. The

electrode is placed into the barrel and both are submerged

in an electrolyte (sodium nitrate). The electrode travels

down the barrel and rotates at the desired rate of twist. As

current passes from the negatively charged electrode

(cathode) to the positively charged barrel (anode), the

metal is removed by electrolysis to produce the grooves by

duplicating the shape of the electrode. During this

operation the electrolyte flows through the barrel under

pressure to remove the reaction products. This prevents the

build up of reaction products on the electrode. Because the

metal strips on the electrode never come in physical contact

with the barrel and reaction products are not given the

opportunity to build up, the electrode does not require any

cleaning or maintenance. In fact, electrodes are only

retired when the plastic core, which contacts the barrel to

provide proper spacing and centering, wears over time. An

electrode will usually remain within the tolerance of 2

thousandths of an inch concentricity tier approximately 3000

inches of barrel. During our tour of the Smith & Wesson

factory, they were rifling six-inch .357 Magnum caliber

barrels and the ECR process took about 60 seconds per

barrel.

White touring the facility, Smith & Wesson generously

provided five consecutively rifled six-inch .357 Magnum

caliber barrels. These barrels were rifled in the presence

of one author. Each barrel was numbered in order of

production, wrapped to avoid damage during transport and

taken to the laboratory for further examination and testing.

PROCEDURE

The five consecutively rifled barrels were numbered in

the order of manufacture. Each barrel was test fired on the

same Smith & Wesson revolver, a Model 681. However, the

marks present on these first sets of bullets were difficult

or impossible to identity. It is believed that this is due

to rapid wear of the new barrels before the microscopic

characteristics stabilize. This phenomenon has been

previously documented in new, unused barrels in studies

conducted by Burdock1 and Matty2.

Their studies required a couple sets of test fires before

the marks began to stabilize. However, the marks in the ECR

barrels did not seem to be stabilizing as quickly. To avoid

any possibility that changing marks might interfere with the

study, fifty rounds of jacketed ammunition were fired from

each barrel to represent the "break-in" period.

After the break-in period, test samples were fired and

collected from each barrel. Microscopic comparisons showed

that the barrels were reproducing their microscopic

characteristics on the test fires. These samples were .357

Magnum caliber, 158 grain jacketed soft point bullets. For

each barrel, six test bullets were collected. The fired

bullets were randomly lettered and placed into envelopes

marked with the respective barrel number.

Three different tests to he conducted by a qualified

examiner were created from the test fired specimens. Each

test consisted of five bullets that were randomly selected

from the envelopes such that one bullet from each barrel was

represented. Two additional bullets were added to each test.

The additional bullets provided for at least two possible

identifications. However, in one test the two additional

bullets had both been fired from the same barrel and

therefore three identifications were possible.

Each test was given to a qualified Firearms-Toolmarks

Examiner in the FBI Laboratory. These tests required

twenty-one different bullet to bullet comparisons. Each

examiner was asked to fill out an answer sheet and mark each

comparison they made as an identification, no conclusion, or

exclusion. For every identification, they were to provide

information as to whether their identification was based on

marks present in the land impressions alone, the groove

impressions alone, or both lands and grooves independently.

This distinction was made because marks produced by the

lands are a result of the reaming process, while the grooves

produce marks that arc a result of the ECR process. Thus,

different areas on the bullet represent different

manufacturing processes. A total of nine examiners completed

a test.

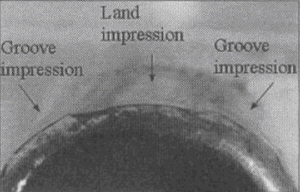

OBSERVATIONS

When the barrels were examined in the laboratory it was

noted that the rifling had the general appearance of

conventional rifting. However, upon closer inspection it was

noticed that the shoulders between lands and grooves were

not as sharp as commonly seen in broached, button, or hammer

Forged rifling. This was also apparent upon examination of

the test tired bullets, which also had a less defined

shoulder between land and groove impressions (Figures 1

through 3).

Figure 1.

Photograph of a test fired bullet showing the

rounded shoulders of the land and groove

impressions.

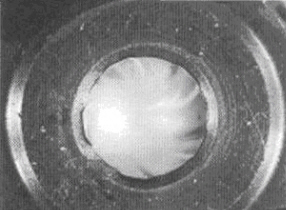

Figure 2.

Photograph of the base of the test

fired bullet showing the rounded shoulders of the

land and groove impressions.

Figure 3.

Photograph of the muzzle end of a lest barrel,

showing the rifling.

The general rifling characteristics of

these bullets were measured and are listed below:

Five Grooves, Right Twist

Land Impression Width: 0.097"-0.100"

Groove impression Width: 0.116"-0.120"

RESULTS

With the exception of one of the authors, all nine of

the qualified Firearms-Toolmarks Examiners in the FBI

Laboratory participated in this study. Upon completion of

the tests, the results were collected and analyzed. The

responses from the nine examiners included no false

identifications or false elimination's. All examiners

reported that the identifications that they made could he

made independently on the land or groove impressions. In

three of the tests there was a true identification that was

marked as a "no conclusion." However, only false positive or

false negative responses were considered incorrect since a

"no conclusion" does not exclude the possibility that the

bullets could have been tired from the same barrel.

CONCLUSIONS

Based upon one author's personal observations during the

comparison of test fired bullets from each barrel, it was

clear that marks were consistently reproduced. Further,

these reproduced marks were clear on both land and groove

impressions, which is important since they would each he the

result of two different manufacturing processes (Figures 4 &

5).

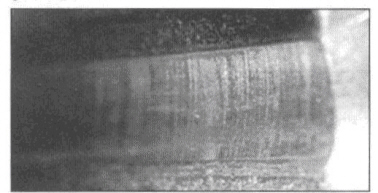

Figure 4.

The marks left by the reaming

process are visible on the top of the land in a test

barrel.

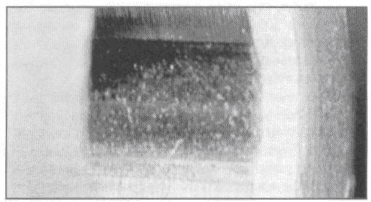

Figure 5.

The marks left on the grooves are visible here. A

speckled pattern is visible from the removal of

metal during the ECR process.

The

results of the tests are also very positive. Without

exception, all the examiners reported correct results. There

were no false identifications reported which clearly

indicates that the marks left on the bullets are unique to a

specific barrel. This was expected in reference to marks

produced by the lands, which are the result of a reaming

operation. Hall3 has previously documented the

uniqueness of marks produced by reaming. The results in this

study serve to further support those reported in previous

studies.

Additionally, each examiner reported that it was possible to

effect identifications based on the marks in the groove

impressions alone. These marks are the result of the

electrochemical rifling. This clearly indicates that the

electrochemical rifling does produce unique and identifiable

microscopic marks.

ACKNOWLEDGMENTS

The authors would like to thank Smith & Wesson for

providing the barrels for testing and for placing their

extremely knowledgeable staff at our disposal.

The authors would also like to thank all the examiners in

the Firearms-Toolmarks Unit who took the time from their

busy caseloads to assist in this study.

REFERENCES

-

Burdock, John E., "A General

Discussion of Gun Barrel Individuality and an

Empirical Assessment of the Individuality of

Consecutively Button Rifled .22 Caliber Rifle

Barrels," AFTE Journal, Volume 13, No. 2, 1981, pp.

84-95.

-

Batty, William, "A Comparison

of Three Individual Barrels Produced from One Button

Rifled Barrel Blank," AFTE Journal, Volume 17, No.

3, July 1985, pp. 64-69.

-

Hall, E. "Bullet Markings From

Consecutively Rifled Shilen DGA Barrels," AFTE

Journal, Volume 15, No. 1 January 1983, pp. 33-53.

|